IST-2001-33522 OMEGA

Correct Development of Real-Time Embedded Systems

Project case studies

|

EADS SPACE

Transportation case study

description This case study presents an extract of the Flight Software of the

European Ariane 5 Launcher and focuses on relevant

real time behaviours. The objective of this Ariane 5 Flight Software

is to control the launcher mission from lift-off to payload release. This

software operates in a completely automatic mode and has to handle both the

external disturbances and the hardware different failures that may occur during

the flight. This case study presents the most relevant points required for such

an embedded application and focuses on the real time critical behaviour. Stages

The launcher is composed of 3

stages: EAP stage, EPC stage and ECS stage.

Mission

The mission is composed of several phases, each one corresponding more

or less to the permanent working point of a launcher stage. At the end of a

permanent working of the launcher, a transition is performed to reach a new

permanent working. This case study models the two first phases of the flight

and the associated transitions: 1.

Ground phase

2.

Transition

from ground phase to EAP phase (lift-off) The lift-off procedure starts by a EPC (Vulcain

engine) ignition. The Vulcain engine is monitored

during some seconds (pressure, temperature, thrust …).

3.

EAP Phase

4.

Transition from

EAP phase to EPC Phase (EAP release) During this transition, EAP are released.

The control / command shall take dynamically into account the change of

the launcher configuration: only one engine (EPC) shall be controlled instead

of 3 previously (EPC+2 EAP), some sensors in the EAP are lost. The NEXT phases (EPC, ECS and BAL) are not described in this case study. Modelling and verification examples An embedded

space software such as the one of the Ariane 5

launcher presented above is composed by several modules which can have

different types of behaviours but which always strongly interact (from a

functional interface point of view and/or from a real time point of view).

Roughly speaking, it exist two main types of functional behaviours: -

cyclical synchronous

execution (i.e. all the processes have a specific period and phase; they

received their inputs at the start of their periods and shall produce their

outputs before a given delay, which shall not be greater than their execution

period) -

non cyclical

execution (synchronised or not with the cyclical synchronous process depending

of their required precision; their execution can depend from a date or from a

process external event). Examples of

these two types of behaviour are given below. In order to

validate (by simulation or by proof) the software behaviour, a part of the

environment shall also be described. The environment can contain part of the

spacecraft hardware (valves, pyrotechnic commands…), the physical environment

(ground control centre, wind for an atmospheric phase, star and moon for some

sensors, other spacecraft…), and part of the software (or more generally of the

computer based system) which is not described in the model (as a numerical

algorithm, a bus protocol, etc). Some examples of environment description are also given

below. Software

modelling: asynchronous behaviour

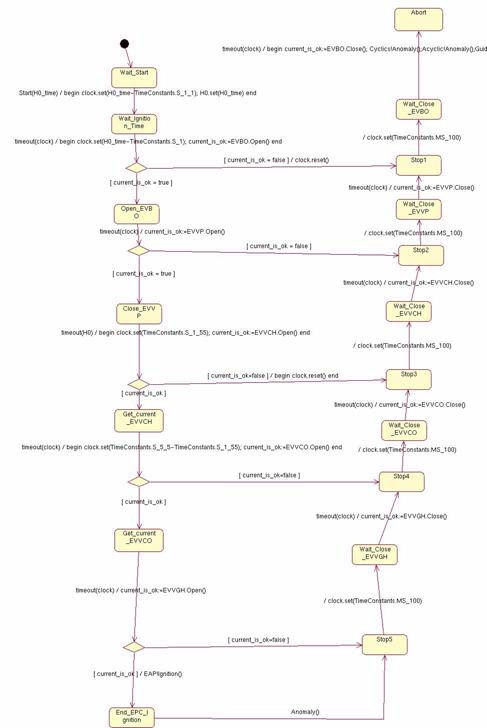

The following

automaton is an example of asynchronous behaviours of the flight software. It describes

the EPC behaviour. The EPC

behaviour has the particularity to include the immediate recovery following

failure detection. In the following automaton, the left part describes the

stage ignition sequence. The right part describes the stage stop sequence.

Depending on the step where the anomaly has been detected, the stop sequence

shall start at a different point (these sequences are a simplification of the

real ones). These two sequences are timed.

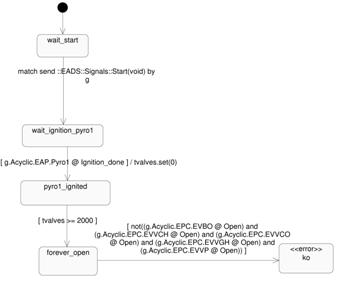

The lift-off is characterised by the ignition of the Pyro1

object. Thus, this property is informally specified in the following way: If the Pyro1 object (of class Pyro)

entries the state “Ignition_done”, then: -

All the instance of the valve class

shall be in the “Open” state 2 seconds after the transition of a pyrotechnics

command automaton to the “Ignition_done” state and

then remain in this state forever. The following automaton formalizes this property:

The

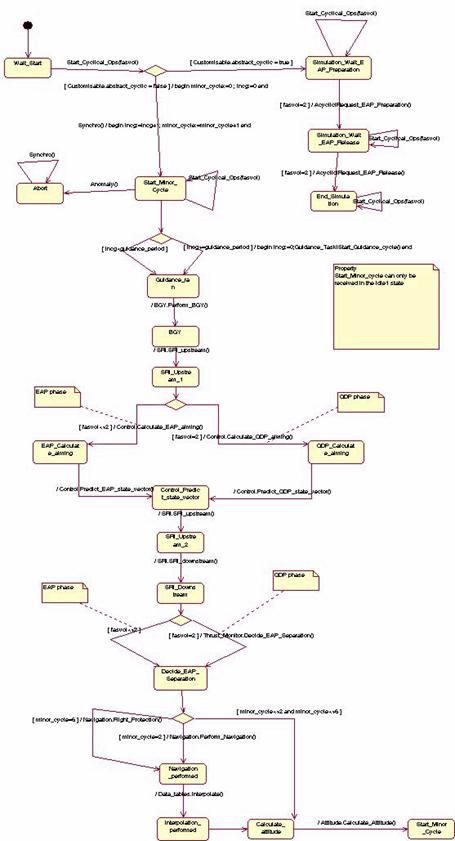

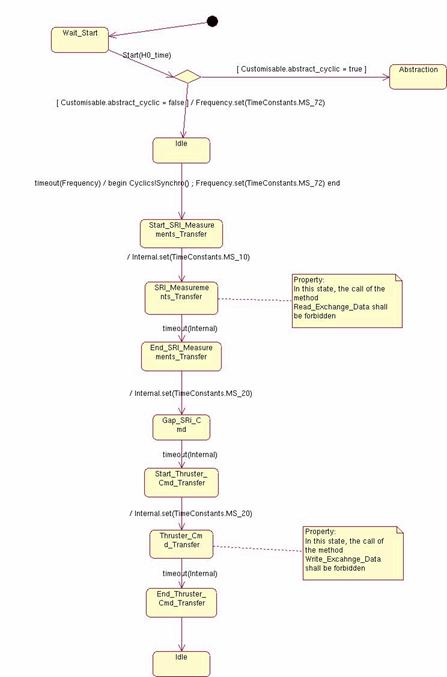

software model: cyclical synchronous behaviour

The following

automaton specifies a basic cycle execution. It describes the sequence of the

flight control command algorithms (navigation, guidance, control). It is

periodically activated

In order to verify the correctness of the real time software

design, this case study constains also the

description of the multitasking (task or thread definition, priorities between

tasks) and the CPU consuption of each algorithmic function (associated to a

task). For each task, a constant priority is

defined in the task constructor:

Then, each function can declare its CPU

cunsumption:

Example of

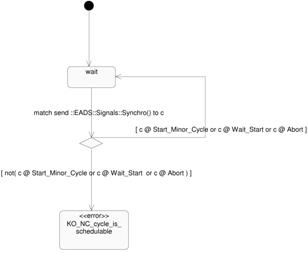

property: The main property of the basic cycle is to finish its

execution before its deadline (i.e. before being requesting to restart a new

execution cycle). This property is formalised by the following automaton. The “synchro” signal, which commands the start of a software

cycle, shall be received only in the “idle” state, i.e., when the treatments

associated to the previous cycle are achieved.

The

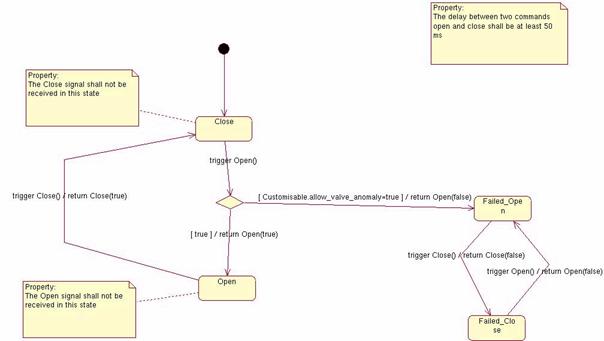

environment model: a valve

The following

automaton describes a valve behaviour with its

potential failure scenario. When an open command is received, the valve can

reject the command and enter a failed state.

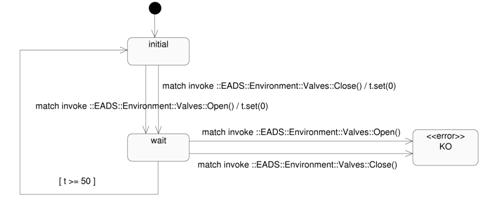

This property is formalized by the following automaton. When

one of the two signals “Close” or “Open” is received by the valve from the

software, a timer (named “t” in the example) is armed. If another signal is

received before 50ms, the automaton enters an error state.

The

environment model: the 1553 bus

The flight control computer communicates with the launcher

equipment with a 1553-MIL bus. The 1553 bus protocol uses an exchange memory

between application software and the hardware bus. The chronology is the

following: -

For a command sent to a piece of

equipment (receive transfer in the 1553 terminology): -

The application software writes in the

exchange memory. -

At a predefined time, the low-level

software read the exchange memory and performs the physical bus transfer. -

For a measurement read from a piece of

equipment (transmit transfer in the 1553 terminology): -

At a predefined time, the low-level

software performs the physical bus transfer and writes the exchange memory. -

The application software reads in the

exchange memory. The application software shall not read or write the

exchange memory at the time foreseen for the low-level transfer. In order to respect the real time properties (between a

measurement read from the bus and a command write on the bus), a bus frame is

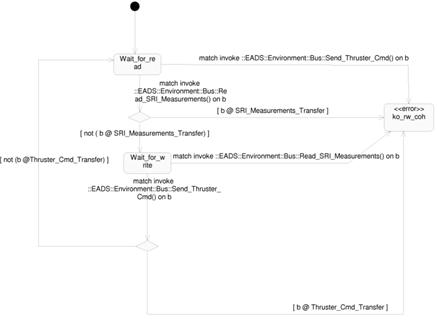

constructed, i.e., a timed slot is allocated to each transfer. This is described by the following automaton:

This previous property can then be expressed by: -

In the state SRI_Measurements_Transfer,

the method Read_Exchange_Data shall not be called. -

In the state Thruster_Cmd_Transfer,

the method Write_Exchange_Data shall not be called. This property has been completed by a property of sequence

between the measurement and the command. If the software behaves correctly, a

measurement shall always precede a command. Thus, this property has been

formalised by the following automaton:

|